Description

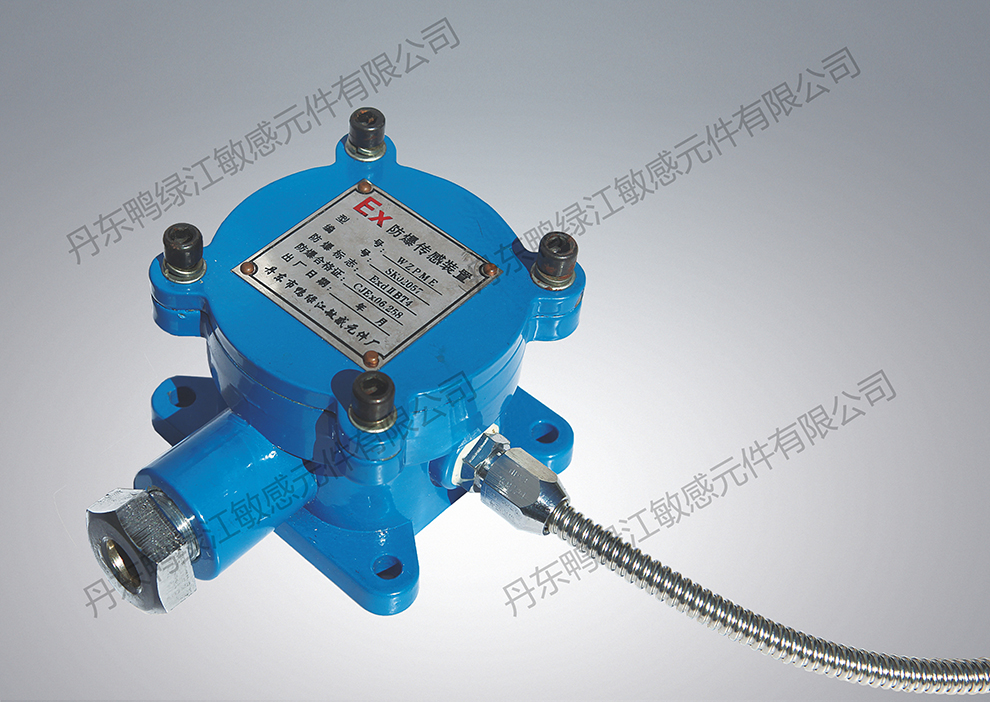

The product's leads are protected by protective sleeves and equipped with an independent explosion-proof junction box. This product has strong sealing performance and can be used for single end and double end wiring. It is suitable for motors operating in explosive gas environments and is safe and reliable. The product meets the explosion-proof standards of GB3836.1 and GB3836.2.

Technical parameters

| Graduation | Measuring range | Accuracy class | 0 ℃ resistance value | Detection current | Insulation resistance |

| Pt100 | -50℃~200℃ | ClassA | 100Ω±0.06Ω | ≤1mA | DC500 V≥200MΩ |

| ClassB | 100Ω±0.12Ω |

Temperature measuring end material Metal | Leads | ||||

| Length | specification | Insulation material | Operation temperature | Shield | |

Standard lead length 1000mm User defined non-standard lead length | 2×0.2mm2 3×0.2mm2 4×0.2mm2 | Teflon | -50℃~200℃ | With or without shielding | |

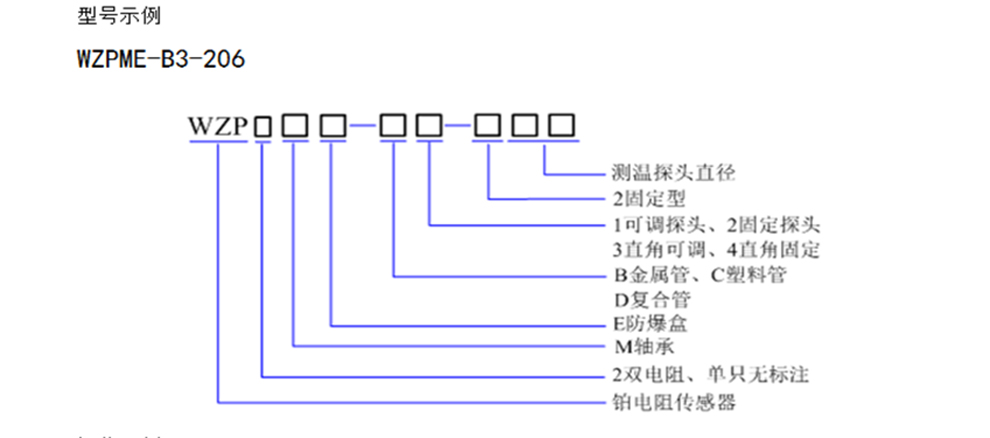

Ordering Example

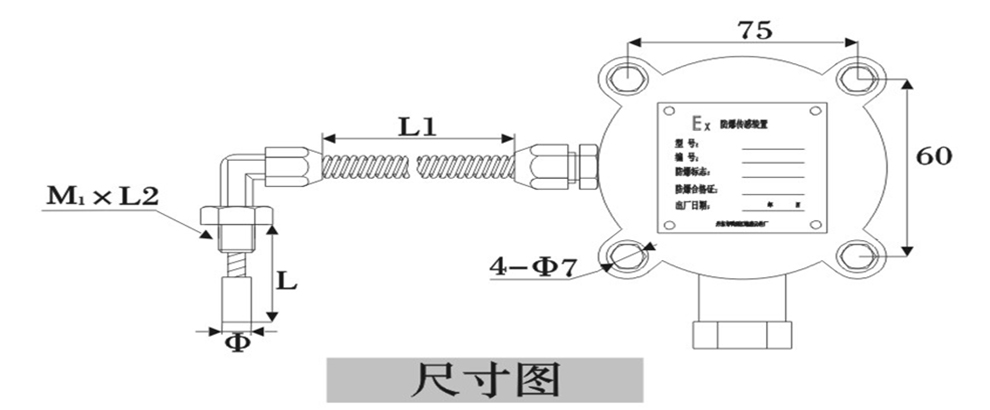

Example:WZPME-B3-206/45-M12×1-1000

45 | Installation hole depth |

| M12×1 | Temperature measuring end thread |

| 1000 | Length of protective sleeve |

Can be wired at both ends

Installation method

Check if the model of the sensor is correct, and insert the temperature sensor into the temperature measurement hole of the motor bearing according to the design requirements.Adjust the direction of the lead wire, and then tighten the temperature measurement end fastening bolt to lock it. Fix the explosion-proof junction box and pay attention to the direction of the leads in the junction box. Fix the lead wire along its routing position, paying attention to leaving a certain margin for the wire and protective tube. Check and verify if the wiring of the sensor is correct.The shielding wire should be reliably grounded, and if there are no abnormalities, close and install the explosion-proof box.

After the sensor is installed, use an ohmmeter to measure the resistance of the sensor based on the actual temperature of the environment and check if it is normal.

QQ聯(lián)系

QQ聯(lián)系 一鍵撥號

一鍵撥號 關(guān)注微信

關(guān)注微信