Description

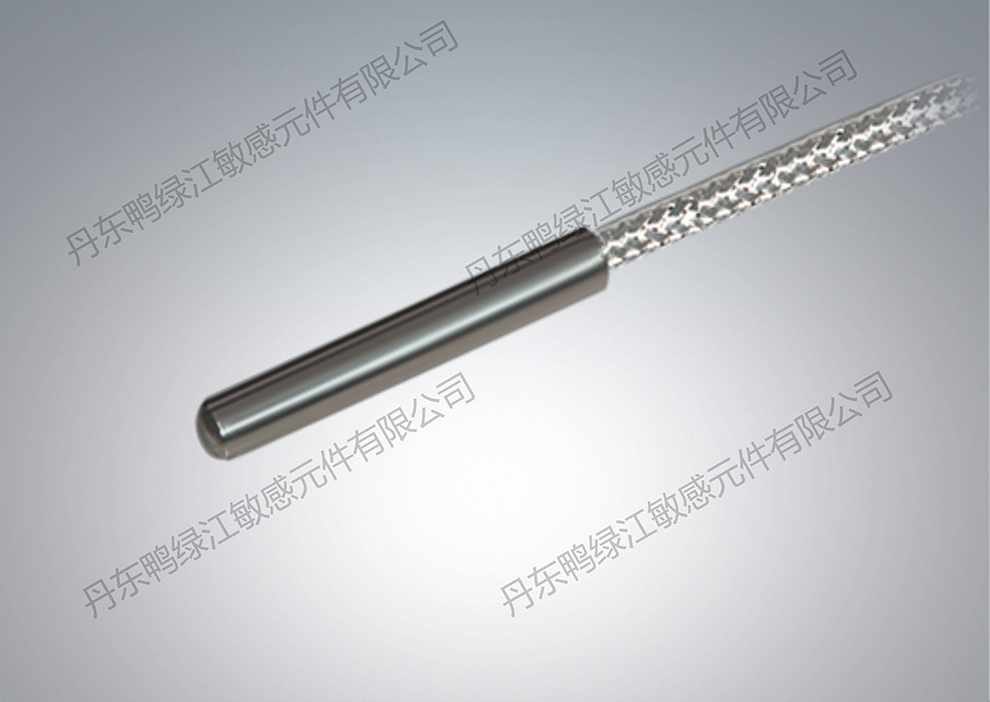

The winding platinum thermistor temperature sensor is used for temperature measurement of motor and transformer windings. It is installed in the end windings of the motor and transformer and can be installed separately according to the three-phase winding. This sensor has the characteristics of earthquake resistance, voltage resistance, high accuracy, good linearity, rapid thermal response, vacuum immersion resistance, small size, high sensitivity, and easy installation. The sensor probe shell can be customized to different materials such as metal, ceramic, PTFE, etc. according to the usage environment requirements

Technical parameters

| Temperature measuring end material | Leads | ||||

| Length | Length specification | Insulation material | Operation temperature | Shield | |

| Ceramics | Standard lead length 1000mm | 2×0.2mm2 | Teflon | -50℃~200℃ | With or without shielding |

User defined non-standard lead length | 3×0.2mm2 | ||||

| 4×0.2mm2 | |||||

Product Features

1. The temperature sensor probe shell of this model can be customized to different materials such as metal, ceramic, PTFE, etc. according to the usage environment requirements.

2. The temperature sensor lead material of this model is Teflon, and different models such as shielding, stranding, and single can be customized according to the usage environment requirements.

3. This model of temperature sensor can be customized with explosion-proof, high-voltage, and insulated temperature sensors

Model and specification description

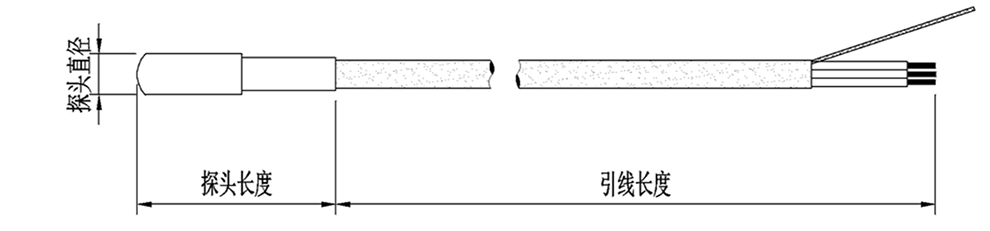

| Model | Probe diameter (mm) | Probe length (mm) | Diameter of protective tube (mm) | Length of protective (mm) | Wire length (mm) |

WZP-T (Example of ceramic probe) | Recommend | Recommend | Recommend | Recommend | Recommend |

| Φ6 | 38 | Φ 5 wax tubes | 500 | 1000 | |

| Φ8 | Customizable | 1000 | 1500 | ||

| Customizable | Unblockable | ||||

| Standard without matching | Customizable | ||||

| Model | Probe diameter (mm) | Probe length (mm) | Diameter of protective tube (mm) | Length of protective (mm) | Wire length (mm) |

WZP-J (Example of metal probe)) | Recommend | Recommend | Recommend | Recommend | Recommend |

| Φ3 | 20 | Φ4 wax tubes | 500 | 1000 | |

| Φ4 | 30 | Customizable | 1000 | 1500 | |

| Φ5 | 40 | Customizable | Unblockable | ||

| Φ6 | 50 | ||||

| Customizable | Customizable | Standard without matching | Customizable | ||

Ordering Example:WZP-J104/20-P3×2000

| WZP-J | 104 | 20 | P3 | ×2000 |

W: Temperature instrument | 1: No fixed device | Probe length (mm) | P: The wire has a shielded wire No shielding, no representation | Wire length |

| Z: Thermal resistance | ||||

| 04: Temperature measurement end diameter Φ four | ||||

P: Platinum thermistor P2: Double platinum thermistor | 2: Two wire system (red, white) 3: Three wire system (1 red, 2 white) 4: Four wire system (2 red, 2 white) 6: Six wire system (2 red, 4 white) | |||

J: Metal temperature measuring probe | ||||

| T: Ceramic temperature measuring probe | ||||

| S: Insulation temperature measurement terminal |

Note

1. During installation, protect the sensor lead out cable and strictly prohibit forceful pulling;

2. During the AC voltage withstand test of the motor, the sensor wire should be short circuited to ground, and the shielding wire should be grounded;

3.After the installation and connection of the sensor are completed, it is necessary to verify whether the wiring is correct and confirm before proceeding.It can avoid damage caused by strong electricity mistakenly connecting to sensors;

4. When the storage period of the sensor exceeds 1 year, the temperature resistance value and insulation resistance value of the sensor should be tested before installation to ensure good sensor performance;

QQ

QQ Speed-dial

Speed-dial Follow WeChat

Follow WeChat