Description

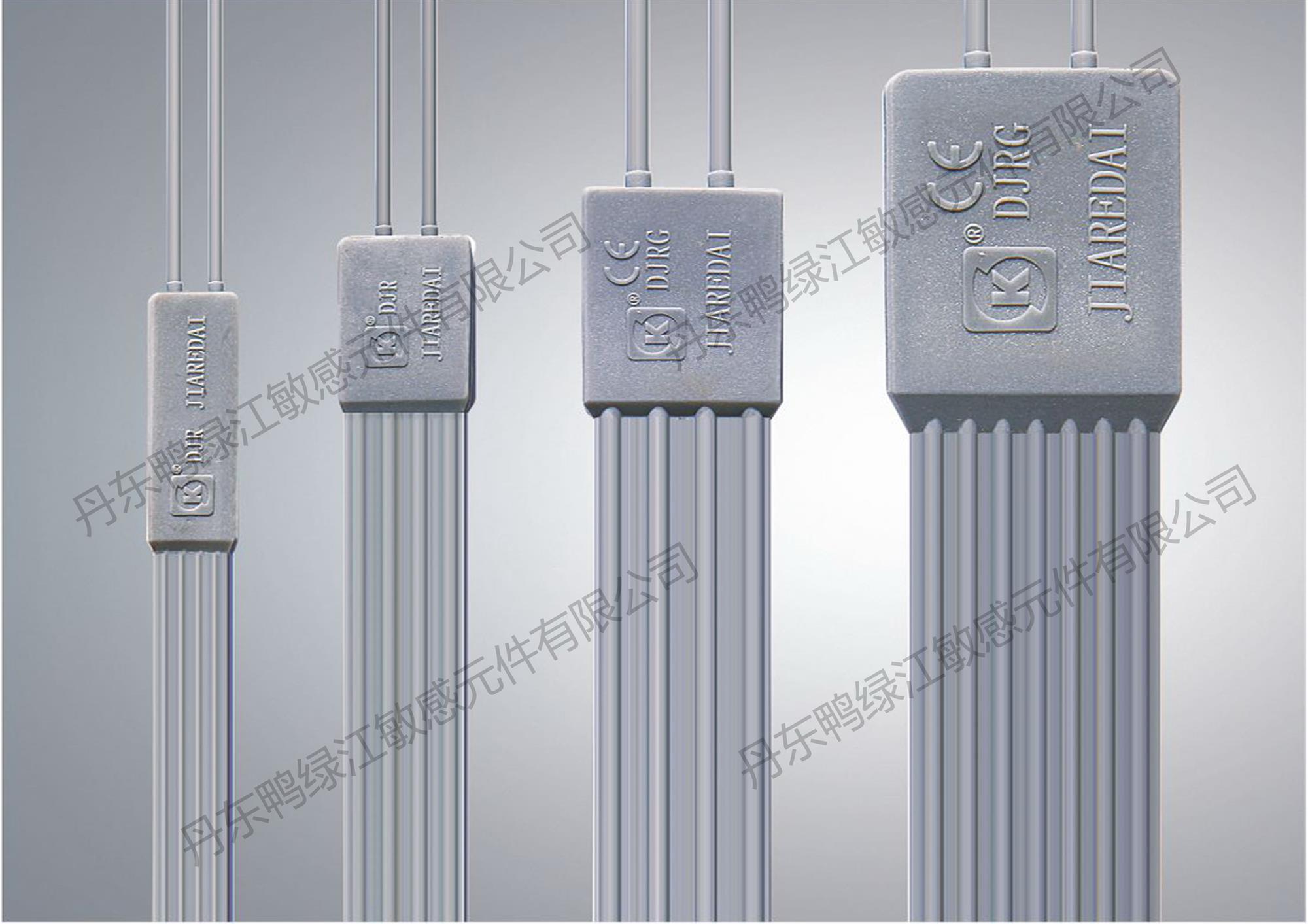

The silicone moisture-proof heating belt body insulation material adopts modified silicone rubber, which has good insulation performance and safe and reliable operation. The explosion-proof type is suitable for high-voltage motors operating in explosive gas environments

Technical Parameter

Basic model and parameters

| Model | L×W×Thickness mm | Lead length mm | Power W | Voltage V | Motor specifications; |

DJRA-230/40 | 550×16×3 | 160 | 40 | 230 | H132-H160 |

DJRA-230/50 | 680×16×3 | 900 | 50 | 230 | H180-H200 |

| DJRA-230/60 | 900×16×3 | 950 | 60 | 230 | H225-280 |

| DJRA-230/80 | 1050×16×3 | 1050 | 80 | 230 | H315 |

| DJRA-230/110 | 630×15×2 | 1150 | 110 | 230 | H315 |

| Model | L×W×Thickness mm | Lead length mm | Power W | Voltage V | Motor specifications; |

DJRA-110/30 | 350×16×3 | 440 | 30 | 110 | H100-H112 |

DJRA-110/31 | 460×16×3 | 740 | 40 | 110 | H132-H160 |

| DJRA-110/32 | 630×16×3 | 850 | 50 | 110 | H180-H200 |

| DJRA-110/33 | 800×16×3 | 900 | 60 | 110 | H225-H280 |

| DJRA-110/34 | 950×16×3 | 1000 | 80 | 110 | H315 |

| DJRA-110/35 | 2000×16×3 | 1500 | 110 | 110 | H315 |

| Model | L×W×Thickness mm | Lead length mm | Power W | Voltage V | Motor specifications; |

DJRA-115/30 | 400×16×3 | 480 | 30 | 115 | H100-H112 |

DJRA-115/40 | 550×16×3 | 780 | 40 | 115 | H132-H160 |

| DJRA-115/50 | 680×16×3 | 900 | 50 | 115 | H180-H200 |

| DJRA-115/60 | 900×16×3 | 950 | 60 | 115 | H225-H280 |

| DJRA-115/80 | 1050×16×3 | 1050 | 80 | 115 | H315 |

| DJRA-115/110 | 1350×16×3 | 1150 | 110 | 115 | H315 |

Note: The width of the silicone heating belt is 16mm, 26mm, 37mm, 46mm, 55mm);

26mm: 26 ± 2, thickness 4.5 ± 1; 37mm 37 ± 2, thickness 6 ± 1;

46mm: 46 ± 2, thickness 6 ± 1; 55mm: 55 ± 2,thickness 6 ± 1,

belt length, lead length, power, and voltage can be customized according to user needs;

Model Example:DJRA-220/60-1000×16-1500

DJR | Heated Belt for motor |

| A | Rubber |

| 220 | Voltage(V) |

| 60 | Power(W) |

| 1000 | belt length |

| 16 | belt width |

| 1500 | Lead length |

DJR-E Explosion-proof, moisture-proof heating belt

| width(mm) | Temperature grade | Power(W/m) | insulated Voltage |

| 26 | T3 | ≤60 | AC 3000V1min |

| 26 | T4 | ≤50 |

Model Example:

| DJR | Heated Belt |

E | Explosion-proof |

Ordering Example::DJR-E220/60-1000×26-1500

| 220 | Voltage(V) |

| 60 | Power(W) |

| 1000 | belt length |

| 26 | belt width |

| 1500 | Lead length |

DJRG-E Explosion proof, high-pressure moisture-proof heating belt

⑴Explosion proof, high-pressure moisture-proof heating belt

| Width(mm) | Temperature grade | Power(W/m) | Insulated Voltage |

| 55 | T3 | ≤110 | AC 10KV1min |

| 55 | T4 | ≤95 | |

| 46 | T3 | ≤95 | |

| 46 | T4 | ≤80 | |

| 37 | T3 | ≤80 | |

| 37 | T4 | ≤65 |

⑵High-pressure moisture-proof heating belt

| Width(mm) | Power(W/m) | Insulated Voltage |

| 26 | 80 | AC 3000V1min |

| 37 | 100 | AC 10KV1min |

| 46 | 120 | |

| 55 | 130 |

Model Example

| DJR | Heated Belt |

| G | High-pressure series |

| E | Explosion proof |

Ordering Example::DJRG-E220/120-1500×37-1500

| 220 | Voltage(V) |

| 1120 | Power(W) |

| 1000 | belt length |

| 37 | belt width |

| 1500 | Lead length |

Installation method:

Firstly, confirm whether the rated working voltage of the heating belt matches the power supply voltage used; When using a moisture-proof heating belt, to install it at the shaft extension end of the stator winding; When using two moisture-proof heating belts, one is installed at the shaft extension end and the other is installed at the non shaft extension end; The heating belt is bound at the end of the stator winding and cannot be installed overlapping.

1. Avoid folding or scratches on the heating belt.

2. After shaping the motor winding, then install the heating belt.

3. The heating belt must be tightly attached to the surface of the winding.

4. Do not subject the heating belt to strong tensile force.

5. Hammering and heating are strictly prohibited.

6. It is strictly prohibited to operate the heating belt and motor simultaneously.

QQ

QQ Speed-dial

Speed-dial Follow WeChat

Follow WeChat